Company

Dinamika Tecno has thirty years of experience in the design and production of parts in composite material.

Our core business is the production of industrial automotive components, however, over the years several customers have asked us to design and produce components related to various sectors.

Our production ranges from the automotive field to the nautical one passing through that of design furniture up to the energy sector.

At the basis of each new project there is the same system of customer support, project evaluation, construction of models and molds to then proceed with industrial production.

We supply important brands in the automotive sector with OEM components but we also work for small productions.

Every project is important to us and the quality of our products is our main focus.

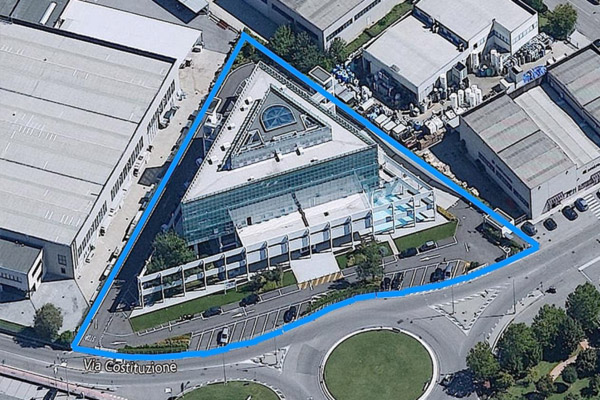

It is a production reality in the Mantuan hinterland, structured in three different operational and production sites.

The offices are managed by a professional, young and dynamic team, capable of operating and adapting to any market requirement.

He is capable of achieving the objectives requested of us by optimizing resources and external collaborations.

The research and development offices are located in Levata di Curtatone.

In Borgo Virgilio, Mantova Z.I.Pioppelle, there are the main logistics office for metal processing, the shipping and packaging warehouse, the management and administrative offices and the technical studio for the design and development with latest generation systems for rapid prototyping with printers. 3D and structured light scanning for measurements and shapes to be transformed into 2 / 3D.

The production plant for the processing of resins and composites is located in Poggio Rusco (MN).

Our structure operates on the Italian territory, markets and manufactures products with different countries in Europe and is able to develop the entire product process, starting from the design phase up to final delivery to the customer.

Our production processes are developed on the quality standards that the market asks of us, with the collaboration of our customers, our technical office and our collaborators, we design, develop and manufacture models with 3D printers, rapid prototypes with the latest technologies. with Robot, 3D laser cutting samples and quick assembly on masks.

Prices, delivery times, and flexibility have characterized our relationship as builders with qualified international customers.

Producing accessories in composite material, spare parts in general, and OEM parts for the first plant is one of our strengths.