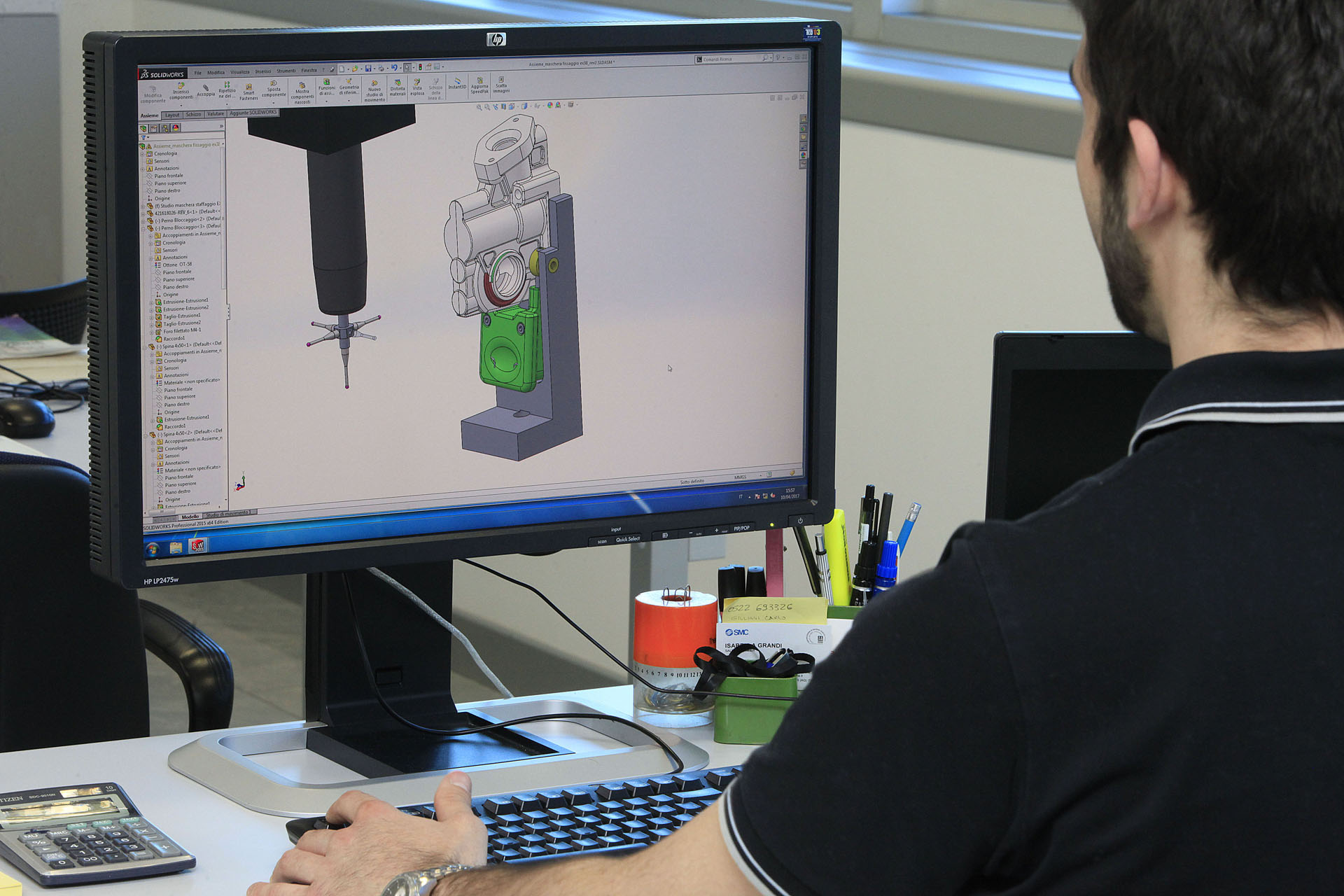

Design

Dinamika carefully follows new technologies combined with development and design. Thus arises the need to co-design with the customer and to participate in its business processes from the initial stages. Design research is carried out to meet the needs of innovation and product diversification, making available the experience gained in the field of mechanical design and industrial design, offering its customers innovative solutions.

Il tutto viene eseguito tramite progettazione 3D, prototipazione rapida e tecniche di reverse enginering.

3D Scan

Scanning allows you to acquire not only objects but also people and is an excellent basis for modifications and adaptations of existing parts.

In fact, through Reverse Engineering it is possible to transform the meshes generated by the scanner into complete CAD models, for further processing, or it is possible to modify and adapt models using special software for organic modeling.

Reverse Engineering

Relief – Scan

Digital acquisition of the object surfaces. Using structured light scanners, a wide range of objects are scanned, from the smallest and most detailed, to the large ones. In this phase, rotary tables or markers on the surface are used. From this phase the 3D shape of the object detected is obtained with a degree of precision that reaches the tenth of a millimeter.

File optimization

We proceed to a cleaning of the “roughness” of the surface and sometimes to the reconstruction of some parts where the survey was not complete. It is often necessary to proceed with the decimation of the triangles to limit the weight of the file.

Surface creation

Creation of Nurbs surfaces, starting from the reconstruction of single curvatures, flat surfaces, holes and chamfers. The different parts obtained are then unified to generate a single polysurface that traces the original scanned model.

Exporting the 3D file

The 3D model can be exported to various CAD compatible formats. The service provides for the creation of dimensioning tables.

Rapid Prototyping

It makes it possible to pass in a few hours from the mathematical model created on the CAD system, directly to an object, even complex, three-dimensional.

Why use a rapid prototyping system:

• We can create a real object, in style, of which to verify the design;

• We can create a real object on which to verify the functionality intended as couplings between the parts and then test it in a real environment;

• We can create a master to be used in the creation of a mold for the subsequent realization in replica of the object;